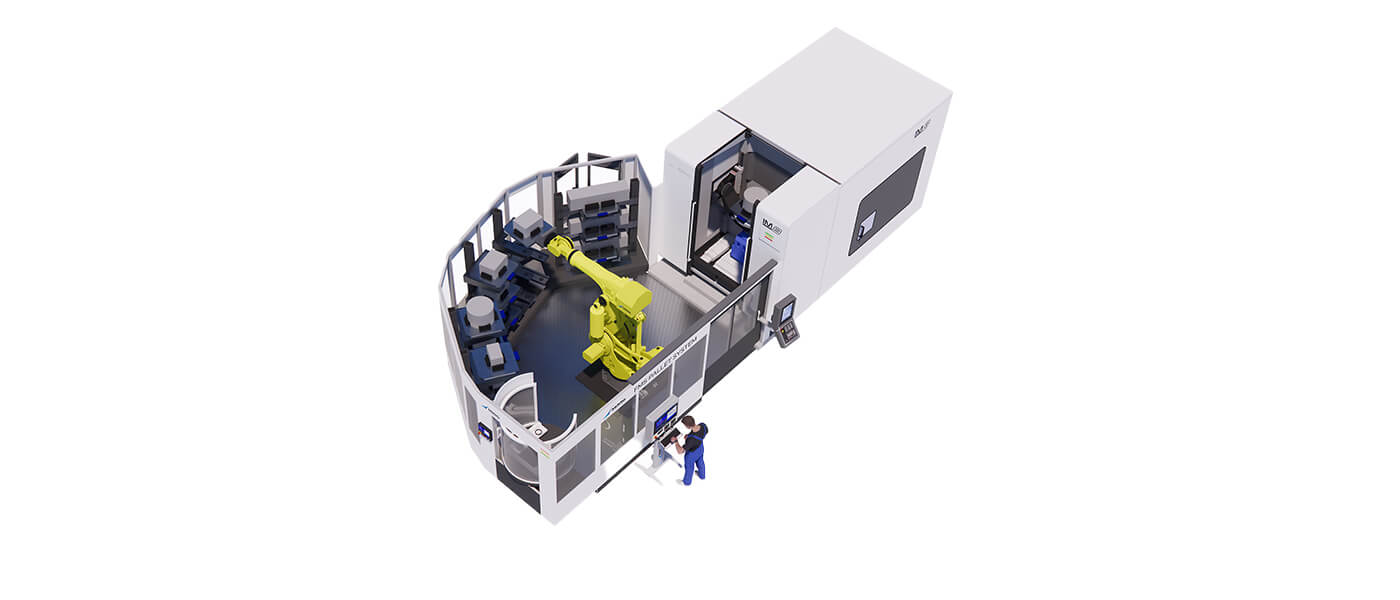

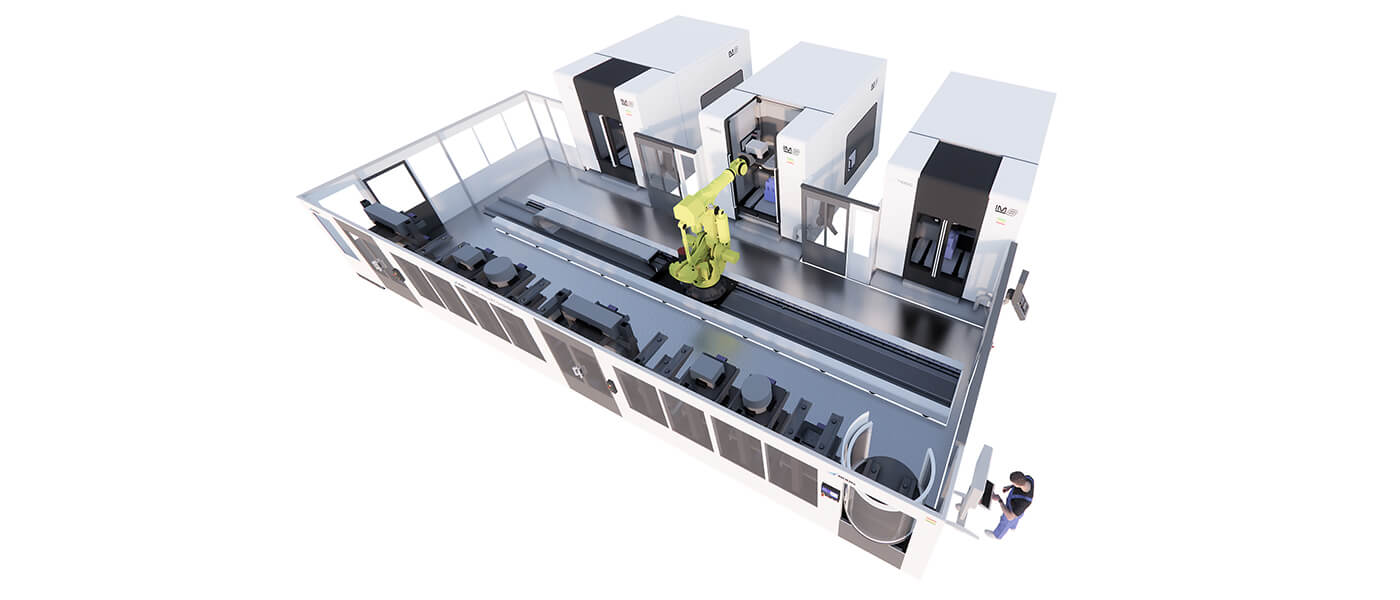

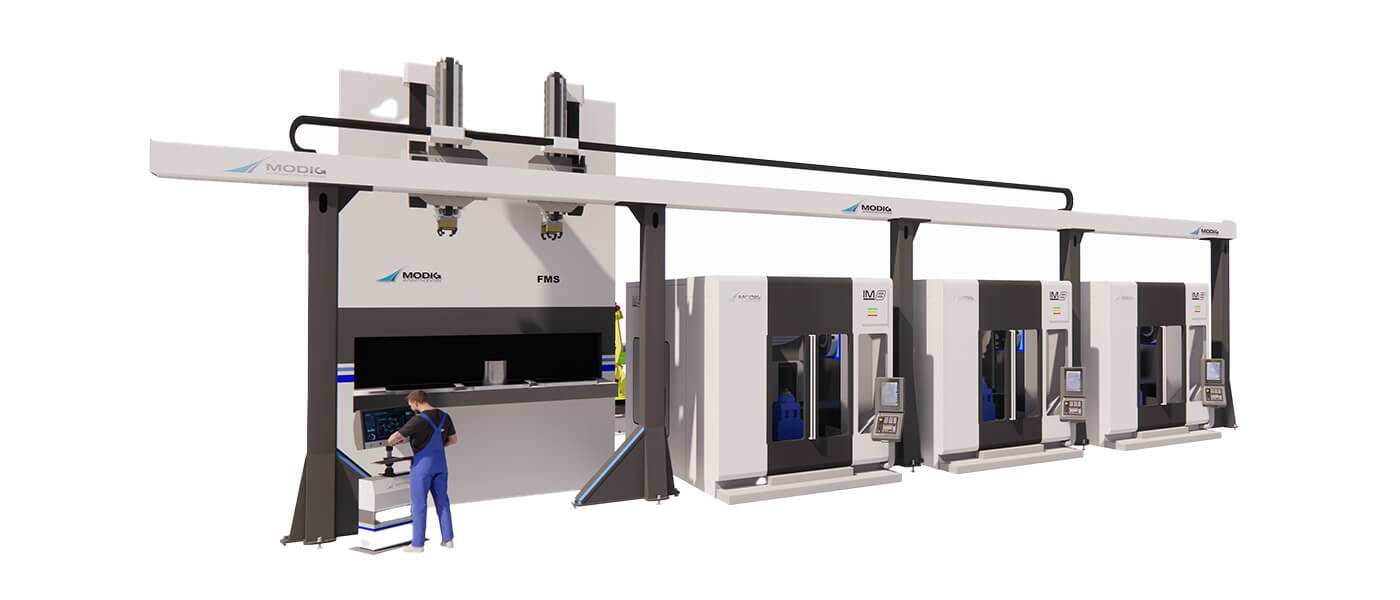

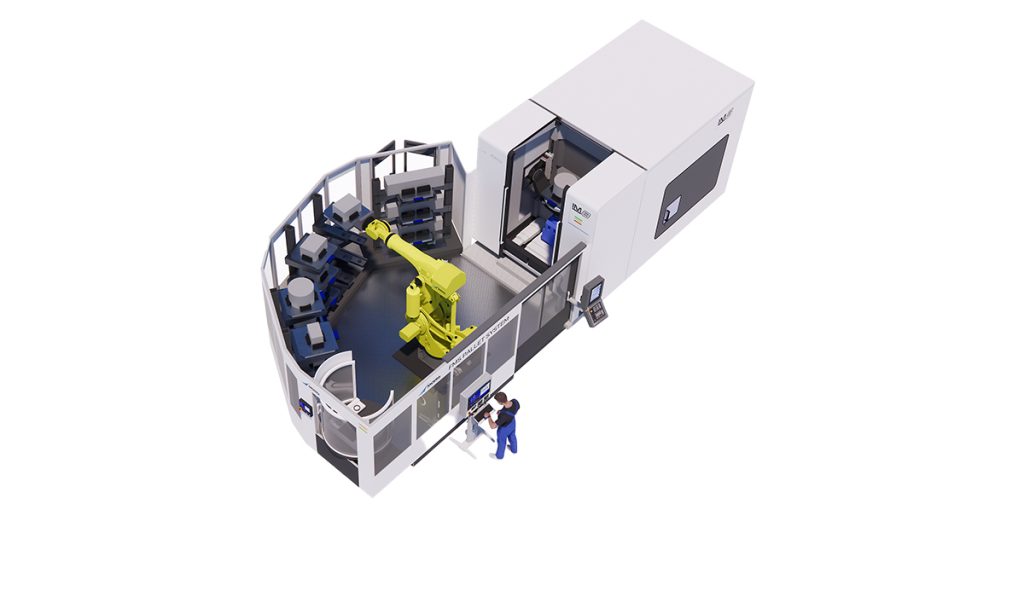

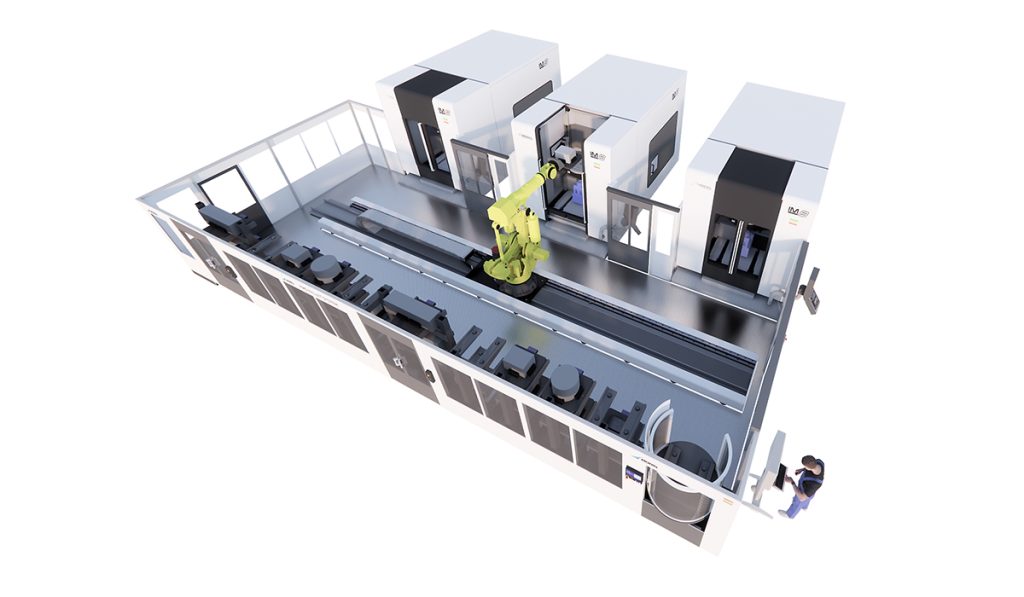

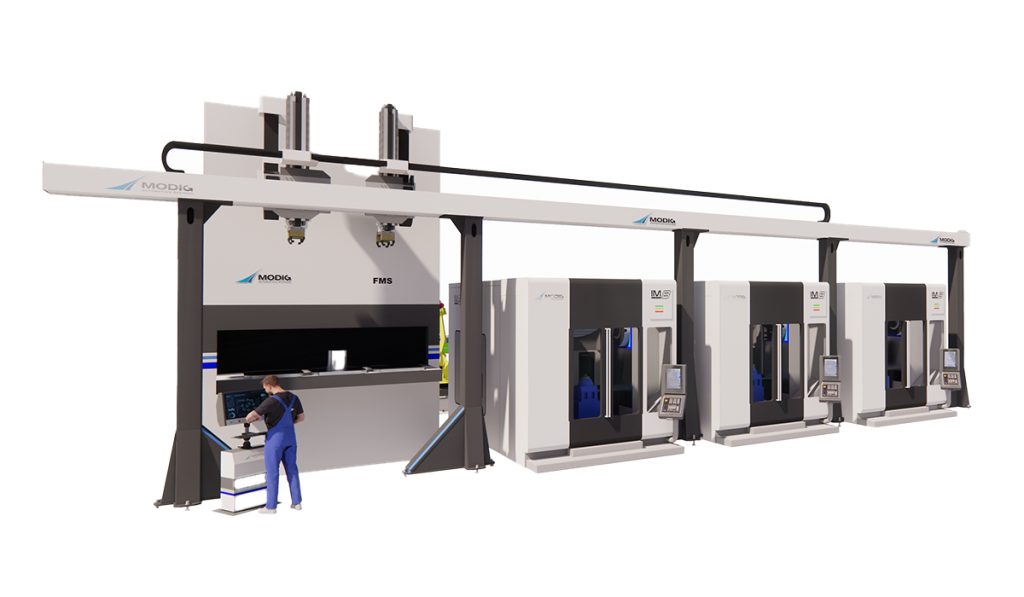

Automation concept for the IM series work different to the other concepts. For this applications we handle the complete part and fixture (machine pallett) which are stored on pallet conveyors or vertical shelf storage systems like Modig FMS storage (automatic paternoster storage). 2-axis linear robots with tandem solution for top- loading/ unloading or six axis robot for front-loading/unloading are the Modig solutions for efficient and flexible machine cells. Solutions are available from single machines up to multiple machine cells.